Overview

India is world’s largest producer of sponge iron produced through direct reduction of iron-ore / iron pellet in the solid state.

Since the higher grade domestic lumpy ore will be exhausted in the next 10 years and value additions to the Iron Ore Fines by various processes such as Pelletisation is the need of present scenario which will be economically beneficial in the long run. The fines are agglomerated by balling them up in the presence of moisture and suitable binders such as bentonites, lime etc into 8-20 mm or larger size. This process of agglomeration of fines is known as Pelletisation.

Sponge iron is a spongy mass of iron which is a metallic product produced through direct reduction of iron ore/ iron pellet in the solid state. It is a substitute for scrap and is mainly used in making steel through the secondary route. The process of sponge iron making aims to remove the oxygen from iron ore or pellets.

We are the fourth largest Sponge Iron manufacturer in India, and as an intermediate product, our Sponge Iron is sold across the country in Assam, Bihar, Chhattisgarh, Gujarat, Jharkhand, Madhya Pradesh, Maharashtra, Meghalaya, Rajasthan, West Bengal and Uttarakhand.

Features

■ Very good reducibility because of high porosity (25-30%)

■ Spherical shape and uniform size give very good bed permeability

■ High strength (150-200 kg ) or more for acid pellets

■ Heat consumption is much less than that of sintering

■ High Iron content and uniform chemical composition, hence lower flux and fuel requirement in the furnace

■ Low FeO

■ Easy handling

■ Its Carbon & FeO is very excellent. Steel Mills who are using DRI for reducing the Carbon, the FeO in our pellet sponge is less which is the plus point for reducing the Carbon

■ Wearing of inner Lining will not take place , as in the Pellet making we are not using Lime

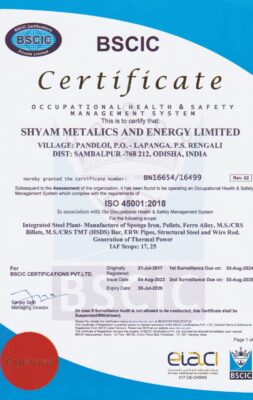

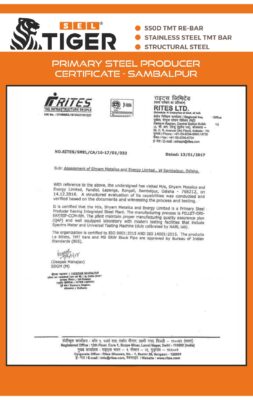

Certificates

Sponge Iron Specifications

| Constituent | Grade 1 |

| % Total Iron | 87 ± 1 |

| % Metallic Iron | 78, min |

| % Metallization | 88, min |

| % C | 0.08 – 0.10 |

| % S, max | 0.03 |

| % P, max | 0.07 |

| % Gangue, max | 8 |